By: Joah Faiello

Quality control (QC) is crucial in manufacturing to ensure products meet high standards of quality, safety, and performance. In boxing, high-quality gear is essential for protecting athletes and enhancing their performance.

Understanding Quality Control

Quality control involves systematic processes to ensure products meet specific standards. In boxing gear manufacturing, QC includes rigorous testing, inspections, and evaluations at every stage of production. Key components of effective QC include:

- Material Selection: Choosing high-quality materials to produce durable and reliable gear.

- Production Techniques: Using advanced methods to maintain consistency.

- Final Product Testing: Ensuring each item meets performance standards for fit, durability, and protection.

The Impact of Consistent Quality Control

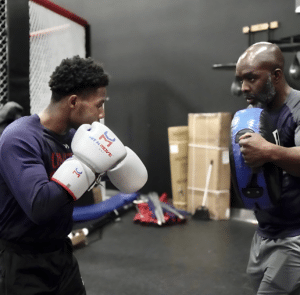

Consistent QC ensures boxing gear is durable, preventing defects that could lead to injuries. Boxing gear, such as gloves, headgear, and wraps, undergoes intense wear and tear. High-quality gear can withstand this, providing athletes with reliable protection and performance over time. Properly constructed gear offers necessary protection for knuckles, wrists, and other vulnerable areas, reducing injury risks during training and bouts.

Durability is a key benefit of consistent QC. Without consistent QC, the gear might fail prematurely, leading to frequent replacements and increased costs for athletes. Injury prevention is another significant impact. Defective or poorly made gear can cause injuries, compromising an athlete’s safety. Properly constructed gear provides the necessary protection, reducing the risk of injuries.

Comfort is another crucial benefit. A comfortable glove reduces the risk of chafing and blisters, enabling boxers to train longer and more effectively. When gloves fit well, they feel like an extension of the hand, enhancing performance. Stylish gloves can motivate athletes, making them feel proud and excited to train. Additionally, a well-designed glove often reflects high craftsmanship, suggesting attention to detail in both aesthetics and performance.

Challenges in Quality Control

Maintaining consistent quality in boxing gear manufacturing presents several challenges, including material defects and variations in production processes. Ensuring that all raw materials meet stringent standards can be difficult, especially when dealing with natural materials like leather. Variations in material quality can lead to inconsistencies in the final product, making rigorous QC checks essential.

Another challenge is maintaining consistency in handcrafted products. While skilled artisans bring a high level of craftsmanship to each product, human error can still occur. By implementing strict QC procedures and leveraging advanced technologies, manufacturers can minimize these variations and maintain a consistent standard of quality.

Hit N Move’s Approach to Quality Control

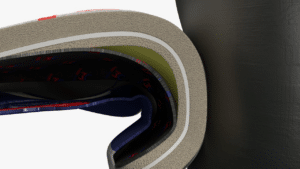

Hit N Move’s QC procedures are meticulous and thorough. Every glove is handcrafted by skilled artisans, ensuring each glove is assembled with precision. This dedication to craftsmanship maintains high standards of quality and consistency. Hit N Move uses special leather sourced from the founder’s home country of Turkey, further underscoring their commitment to quality.

The aerodynamic DR-T padding design is an example of their innovative QC approach. By replicating the weight distribution of a dart, Hit N Move optimizes the padding’s balance and performance to align with the natural mechanics of a punch. This design enhances both the glove’s protective features and the athlete’s punching efficiency.

Additionally, all gloves are designed and engineered in the USA, reflecting a commitment to high standards. This local production ensures the manufacturing process is closely monitored, allowing for immediate adjustments and improvements as needed.

Benefits of High-Quality Boxing Gear for Athletes

High-quality boxing gear offers numerous benefits for athletes. Enhanced safety during training and competition is achieved through comprehensive hand protection, including knuckle and wrist support. Reliable gear also improves performance, as well-crafted gloves feel like an extension of the hand, allowing for better control and stability. The psychological benefits of using trusted equipment can boost an athlete’s confidence and motivation.

The Future of Quality Control in Boxing Gear Manufacturing

The future of QC in boxing gear manufacturing will see the integration of emerging trends and technologies. Automation, advanced materials, and data analytics will play significant roles in enhancing QC processes. Hit N Move is committed to continuous improvement and innovation in QC, ensuring their products remain at the forefront of boxing gear technology.

Moving Forward

Consistent quality control is vital for the safety, performance, and satisfaction of athletes using boxing gear. Hit N Move’s dedication to QC ensures their products meet the highest standards, providing athletes with reliable and high-performance gear. As QC processes evolve, Hit N Move will continue to lead the way in boxing gear innovation.

Final Remarks

For athletes and enthusiasts, prioritizing quality when choosing boxing gear is essential. Hit N Move’s commitment to quality control guarantees their products deliver the performance and protection needed for rigorous training and competition. Explore Hit N Move’s range of products to experience the benefits of their meticulous QC processes.

Published by: Holy Minoza